© 2019 Artlife Techno

Biotech Equipment

Artlife Techno manufactures bioreactors, fermenters, CIP systems, and other equipment for making growth media and cell/microbial growth.

Biotech Equipment

Artlife Techno manufactures bioreactors, fermenters, CIP systems, and other equipment for making growth media and cell/microbial growth.

Workflow

1

Requirements Specification

We study the requirements specification, and assist with its development based on the questionnaires filled by the customer.

2

Design

Having the requirements specification, our engineers select the most suitable configuration of standard modules, or design a customized project. Then the managers issue a detailed proposal indicating the equipment configuration and specifications.

Learn more…

Learn more…

3

Manufacturing

After negotiating the price and entering into a contract, we get the final drawings approved by the customer, and proceed with manufacturing.

Learn more…

Learn more…

4

Factory Acceptance Tests (FAT)

After FAT, the products are packaged into crates compliant to the international standards, and shipped to your site.

Learn more…

Learn more…

5

Installation and Commissioning

Our service team visits the customer site for equipment installation and commissioning. We perform equipment piping hook up, and adjustment.

Learn more…

Learn more…

6

SAT Tests and Documentation

During SAT, our team together with you checks the equipment for compliance with the approved specifications, hands over the final documentation packages, and trains the personnel.

Learn more…

Learn more…

7

Maintenance

Our service engineers are ready to visit any location worldwide.

We deliver spare parts and components after in post-warranty periods.

We deliver spare parts and components after in post-warranty periods.

Bioreactors and fermenters

Artlife Techno product range includes reactors from 30 (pilot) to 15,000 (industrial grade) l capacity. The bioreactors and fermenters we design and build ensure optimal cell/microbial growth conditions.

Bioreactors and fermenters

Artlife Techno product range includes reactors from 30 (pilot) to 15,000 (industrial grade) l capacity. The bioreactors and fermenters we design and build ensure optimal cell/microbial growth conditions.

Control panel

A Siemens controller with a touchscreen for convenient visualization and process control

A Siemens controller with a touchscreen for convenient visualization and process control

Analytical sensor ports

Temperature, pH, DO, conductivity, etc.

Temperature, pH, DO, conductivity, etc.

Gas extraction module

A gas extraction and filtration system with heating/cooling functions.

A gas extraction and filtration system with heating/cooling functions.

Agitator drive

To isolate the media, end seals or magnetic couplings are optionally available.

To isolate the media, end seals or magnetic couplings are optionally available.

Agitator

A mixing device.

A mixing device.

Gas feed module

Automated gas feed controlled by the program and the sensor signals.

Automated gas feed controlled by the program and the sensor signals.

Water gauge

For visual growth monitoring.

For visual growth monitoring.

Sampler

For in-process product composition control.

For in-process product composition control.

Discharge system

A sterilizable membrane bottom valve with no dead zones

A sterilizable membrane bottom valve with no dead zones

Temperature maintenance system

Buffer Feed Module

Aerator

Saturates the culture broth with oxygen or other gases as required.

Saturates the culture broth with oxygen or other gases as required.

Baffles

To intensify mass and heat transfer during growth.

To intensify mass and heat transfer during growth.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Control panel

A Siemens controller with a touchscreen for convenient visualization and process control

A Siemens controller with a touchscreen for convenient visualization and process control

Analytical sensor ports

Temperature, pH, DO, conductivity, etc.

Temperature, pH, DO, conductivity, etc.

Gas extraction module

A gas extraction and filtration system with heating/cooling functions.

A gas extraction and filtration system with heating/cooling functions.

Agitator drive

To isolate the media, end seals or magnetic couplings are optionally available.

To isolate the media, end seals or magnetic couplings are optionally available.

Agitator

A mixing device.

A mixing device.

Gas feed module

Automated gas feed controlled by the program and the sensor signals.

Automated gas feed controlled by the program and the sensor signals.

Water gauge

For visual growth monitoring.

For visual growth monitoring.

Sampler

For in-process product composition control.

For in-process product composition control.

Discharge system

A sterilizable membrane bottom valve with no dead zones

A sterilizable membrane bottom valve with no dead zones

Temperature maintenance system

Buffer Feed Module

Aerator

Saturates the culture broth with oxygen or other gases as required.

Saturates the culture broth with oxygen or other gases as required.

Baffles

To intensify mass and heat transfer during growth.

To intensify mass and heat transfer during growth.

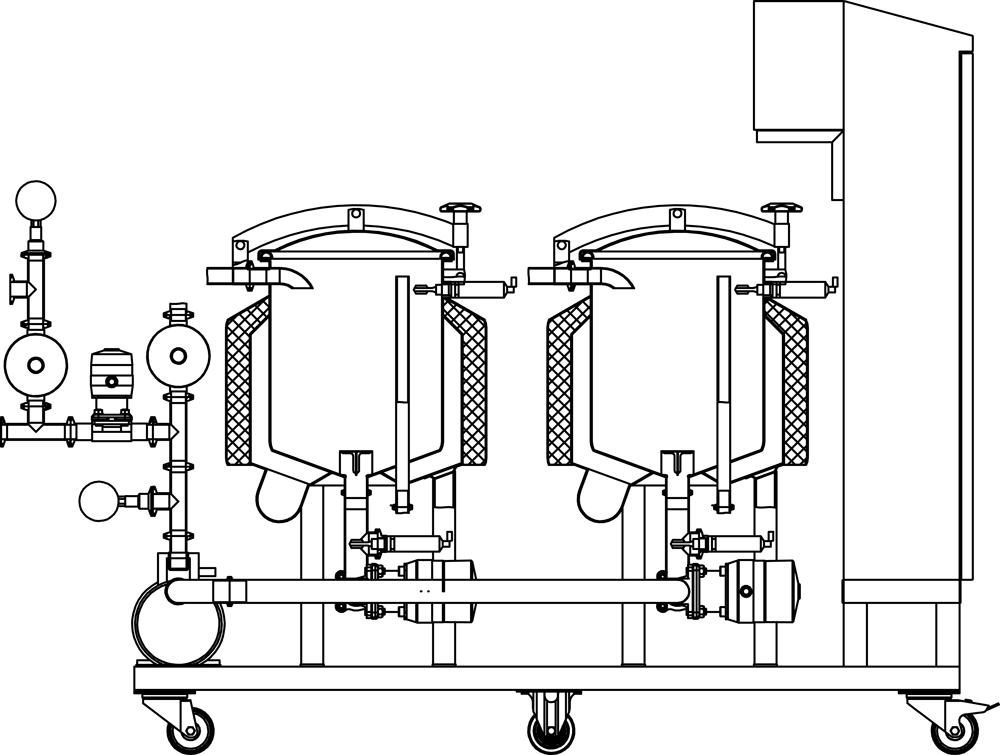

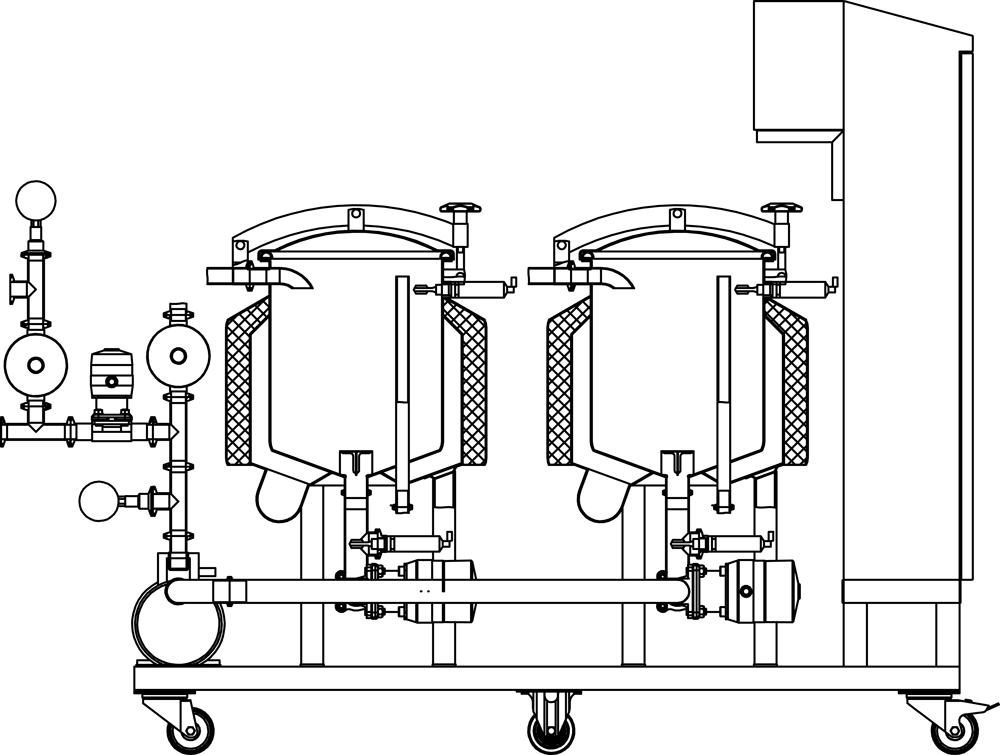

CIP washers

For CIP (Clean-in-Place) washing and sterilization, Artlife Techno makes a number of CIP washers with a range of automation options: from manual control to fully automated systems.

CIP washers

For CIP (Clean-in-Place) washing and sterilization, Artlife Techno makes a number of CIP washers with a range of automation options: from manual control to fully automated systems.

Washing quality control module

Analytical sensors to monitor pH, conductivity of washing/draining liquids.

Analytical sensors to monitor pH, conductivity of washing/draining liquids.

Control panel

A Siemens controller with a touchscreen for convenient visualization and process control.

A Siemens controller with a touchscreen for convenient visualization and process control.

Temperature maintenance system

The system uniformly heats the washing liquid.

The system uniformly heats the washing liquid.

Logger

The logger logs the key wash/sterilization variables.

The logger logs the key wash/sterilization variables.

Sterilization module

The module controls steam supply into the equipment being sterilized, and drains the condensate.

The module controls steam supply into the equipment being sterilized, and drains the condensate.

Washing liquid mixing vessels

The system has as many washing liquid mixing vessels as required.

The system has as many washing liquid mixing vessels as required.

Pumps

The pumps deliver and circulate the washing liquid.

The pumps deliver and circulate the washing liquid.

Piping

Either manual, or automated valves are used.

Either manual, or automated valves are used.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Customized specifications and configurations. The images demonstrate some of the available configurations.

Washing quality control module

Analytical sensors to monitor pH, conductivity of washing/draining liquids.

Analytical sensors to monitor pH, conductivity of washing/draining liquids.

Control panel

A Siemens controller with a touchscreen for convenient visualization and process control.

A Siemens controller with a touchscreen for convenient visualization and process control.

Temperature maintenance system

The system uniformly heats the washing liquid.

The system uniformly heats the washing liquid.

Logger

The logger logs the key wash/sterilization variables.

The logger logs the key wash/sterilization variables.

Sterilization module

The module controls steam supply into the equipment being sterilized, and drains the condensate.

The module controls steam supply into the equipment being sterilized, and drains the condensate.

Washing liquid mixing vessels

The system has as many washing liquid mixing vessels as required.

The system has as many washing liquid mixing vessels as required.

Pumps

The pumps deliver and circulate the washing liquid.

The pumps deliver and circulate the washing liquid.

Piping

Either manual, or automated valves are used.

Either manual, or automated valves are used.

Effluent neutralization systems

Automated biotech/chemical/pharmaceutical effluent neutralization units.

Effluent neutralization systems

Automated biotech/chemical/pharmaceutical effluent neutralization units.

Control panel

A Siemens controller with a touchscreen for convenient visualization and process control.

A Siemens controller with a touchscreen for convenient visualization and process control.

Hydrophobic vent filter

A sterilizing hydrophobic filter.

A sterilizing hydrophobic filter.

Level sensors

Used for automated neutralizer vessel filling/draining.

Used for automated neutralizer vessel filling/draining.

Automated valves

The unit has valves that automatically drain he system as the neutralization process is completed.

The unit has valves that automatically drain he system as the neutralization process is completed.

Jet steam system

Extended exposure to high temperatures for effluent neutralization.

Extended exposure to high temperatures for effluent neutralization.

Access manhole

To access the vessel interior for maintenance, and other purposes.

To access the vessel interior for maintenance, and other purposes.

Heat insulation

A rock wool heat insulation layer sealed into a stainless steel shell.

A rock wool heat insulation layer sealed into a stainless steel shell.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Bioreactors/fermenters questionary

Send your contact details for questionary