© 2019 Artlife Techno

Chemical and Pharmaceutical Equipment

Reactors, crystallizers, Druk and Nutsche filters, other equipment for substance synthesis, refining, and filtration.

Chemical and Pharmaceutical Equipment

Reactors, crystallizers, Druk and Nutsche filters, other equipment for substance synthesis, refining, and filtration.

Workflow

1

Requirements Specification

We study the requirements specification, and assist with its development based on the questionnaires filled by the customer.

2

Design

Having the requirements specification, our engineers select the most suitable configuration of standard modules, or design a customized project. Then the managers issue a detailed proposal indicating the equipment configuration and specifications.

Learn more…

Learn more…

3

Manufacturing

After negotiating the price and entering into a contract, we get the final drawings approved by the customer, and proceed with manufacturing.

Learn more…

Learn more…

4

Factory Acceptance Tests (FAT)

After FAT, the products are packaged into crates compliant to the international standards, and shipped to your site.

Learn more…

Learn more…

5

Installation and Commissioning

Our service team visits the customer site for equipment installation and commissioning. We perform equipment piping hook up, and adjustment.

Learn more…

Learn more…

6

SAT Tests and Documentation

During SAT, our team together with you checks the equipment for compliance with the approved specifications, hands over the final documentation packages, and trains the personnel.

Learn more…

Learn more…

7

Maintenance

Our service engineers are ready to visit any location worldwide.

We deliver spare parts and components after in post-warranty periods.

We deliver spare parts and components after in post-warranty periods.

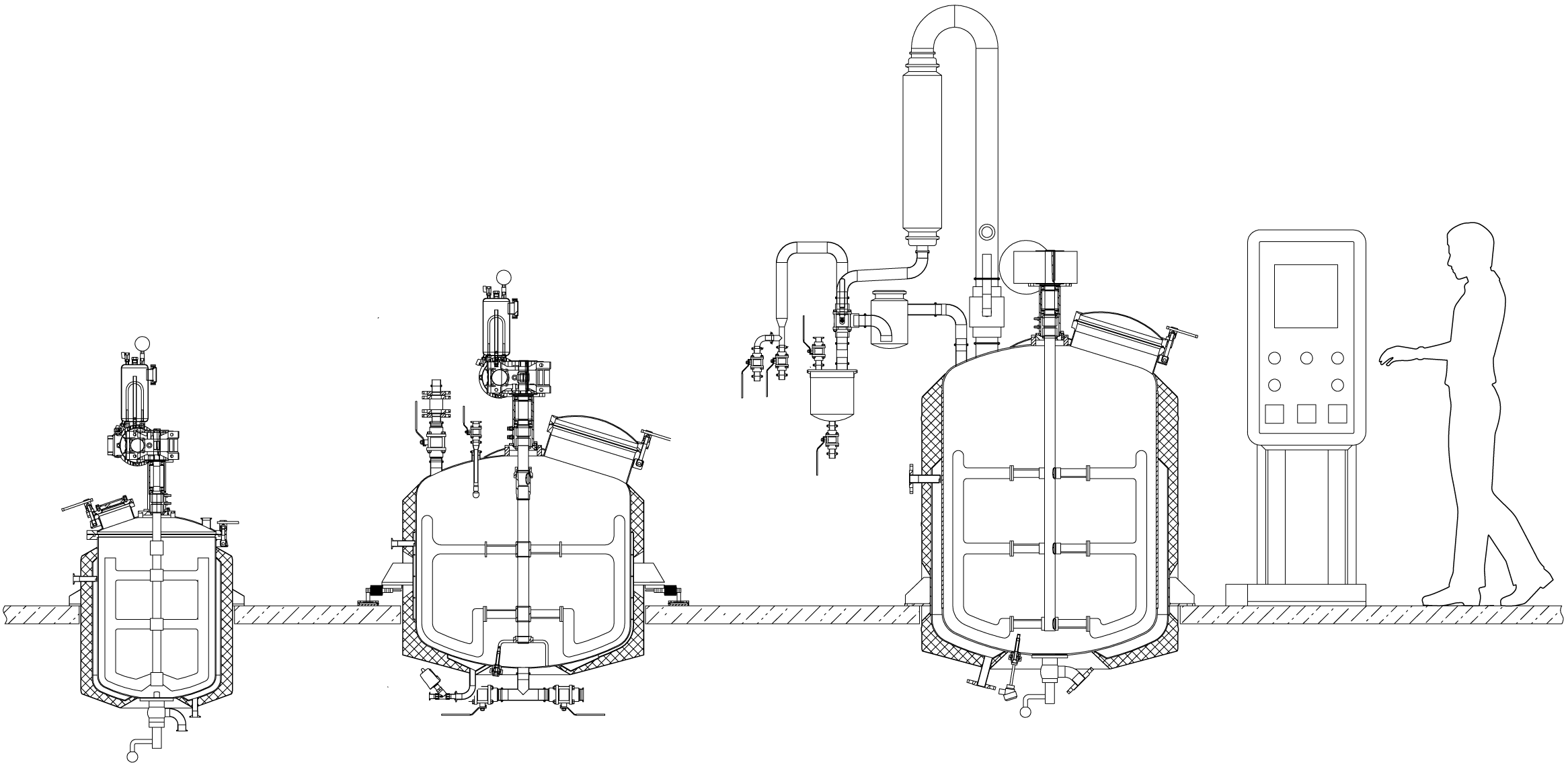

Reactors, Crystallizers

Artlife Techno makes synthesis/refining reactors from 10 to 5,000 l capacity. They are intended for high-pressure processing of explosive, flammable, and aggressive media.

Reactors, Crystallizers

Artlife Techno makes synthesis/refining reactors from 10 to 5,000 l capacity. They are intended for high-pressure processing of explosive, flammable, and aggressive media.

Washing head

Washes the vessel interior.

Washes the vessel interior.

Access manhole

To access the vessel interior for maintenance, and other purposes.

To access the vessel interior for maintenance, and other purposes.

Heat transfer loop

A tube heat transfer loop efficiently and uniformly heats up/cools down the product.

A tube heat transfer loop efficiently and uniformly heats up/cools down the product.

Gate agitator

The agitator uniformly mixes the product throughout the entire volume of the vessel.

The agitator uniformly mixes the product throughout the entire volume of the vessel.

Temperature sensor

A temperature sensor is installed in a protective sleeve. It is hot swappable.

A temperature sensor is installed in a protective sleeve. It is hot swappable.

Thermosyphon

Circulates barrier fluid in the double end seal.

Circulates barrier fluid in the double end seal.

Heat insulation

A rock wool heat insulation layer sealed into a stainless steel shell.

A rock wool heat insulation layer sealed into a stainless steel shell.

Double end seal

Double water-cooled end seals reliably separate the media.

Double water-cooled end seals reliably separate the media.

Bottom valve

A dedicated bottom valve with no dead zones. Opens inwards.

A dedicated bottom valve with no dead zones. Opens inwards.

Exd-rated control panel

With the Exd rating, the panel can be operated in explosive and fire hazard rooms.

With the Exd rating, the panel can be operated in explosive and fire hazard rooms.

Vapor recirculation system

A backflow condenser to condense the vapor and return it into the reactor vessel.

A backflow condenser to condense the vapor and return it into the reactor vessel.

Exd-rated agitator drive

An Exd-rated gear motor suitable for explosive and fire hazard environments.

An Exd-rated gear motor suitable for explosive and fire hazard environments.

Flame arrestor

Protects the vessel contents from fire.

Protects the vessel contents from fire.

Strain gauge system

A strain gauge system is used for component weighing and dosing.

A strain gauge system is used for component weighing and dosing.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

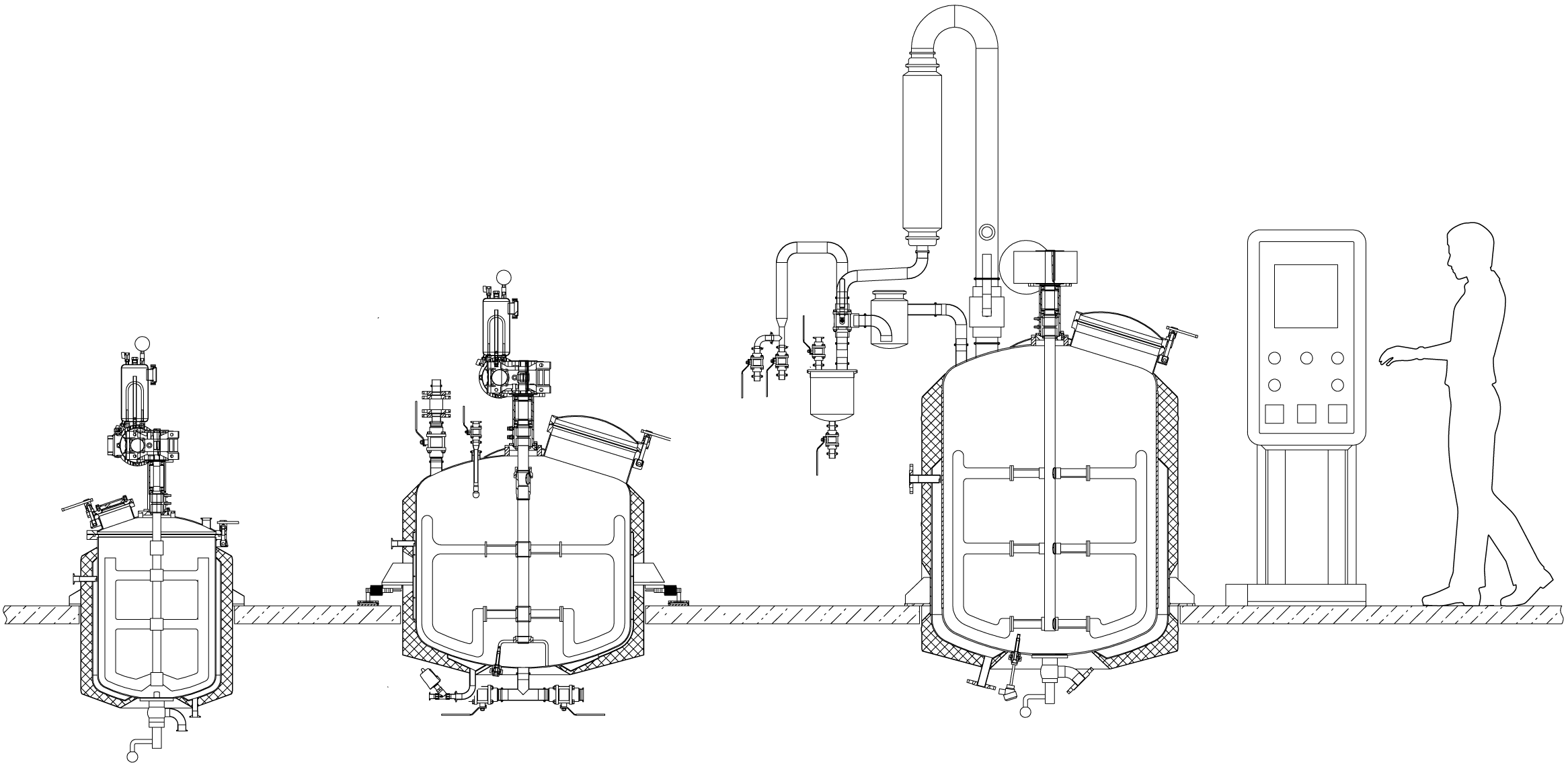

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Washing head

Washes the vessel interior.

Washes the vessel interior.

Access manhole

To access the vessel interior for maintenance, and other purposes.

To access the vessel interior for maintenance, and other purposes.

Heat transfer loop

A tube heat transfer loop efficiently and uniformly heats up/cools down the product.

A tube heat transfer loop efficiently and uniformly heats up/cools down the product.

Gate agitator

The agitator uniformly mixes the product throughout the entire volume of the vessel.

The agitator uniformly mixes the product throughout the entire volume of the vessel.

Temperature sensor

A temperature sensor is installed in a protective sleeve. It is hot swappable.

A temperature sensor is installed in a protective sleeve. It is hot swappable.

Thermosyphon

Circulates barrier fluid in the double end seal.

Circulates barrier fluid in the double end seal.

Heat insulation

A rock wool heat insulation layer sealed into a stainless steel shell.

A rock wool heat insulation layer sealed into a stainless steel shell.

Double end seal

Double water-cooled end seals reliably separate the media.

Double water-cooled end seals reliably separate the media.

Bottom valve

A dedicated bottom valve with no dead zones. Opens inwards.

A dedicated bottom valve with no dead zones. Opens inwards.

Exd-rated control panel

With the Exd rating, the panel can be operated in explosive and fire hazard rooms.

With the Exd rating, the panel can be operated in explosive and fire hazard rooms.

Vapor recirculation system

A backflow condenser to condense the vapor and return it into the reactor vessel.

A backflow condenser to condense the vapor and return it into the reactor vessel.

Exd-rated agitator drive

An Exd-rated gear motor suitable for explosive and fire hazard environments.

An Exd-rated gear motor suitable for explosive and fire hazard environments.

Flame arrestor

Protects the vessel contents from fire.

Protects the vessel contents from fire.

Strain gauge system

A strain gauge system is used for component weighing and dosing.

A strain gauge system is used for component weighing and dosing.

Chemical reactors/filters questionary

Send your contact details for questionary