© 2019 Artlife Techno

Cosmetics manufacturing equipment

Reactors, homogenizers, vessels, and plants for making creams, gels, toothpaste.

Cosmetics manufacturing equipment

Reactors, homogenizers, vessels, and plants for making creams, gels, toothpaste.

Workflow

1

Requirements Specification

We study the requirements specification, and assist with its development based on the questionnaires filled by the customer.

2

Design

Having the requirements specification, our engineers select the most suitable configuration of standard modules, or design a customized project. Then the managers issue a detailed proposal indicating the equipment configuration and specifications.

Learn more…

Learn more…

3

Manufacturing

After negotiating the price and entering into a contract, we get the final drawings approved by the customer, and proceed with manufacturing.

Learn more…

Learn more…

4

Factory Acceptance Tests (FAT)

After FAT, the products are packaged into crates compliant to the international standards, and shipped to your site.

Learn more…

Learn more…

5

Installation and Commissioning

Our service team visits the customer site for equipment installation and commissioning. We perform equipment piping hook up, and adjustment.

Learn more…

Learn more…

6

SAT Tests and Documentation

During SAT, our team together with you checks the equipment for compliance with the approved specifications, hands over the final documentation packages, and trains the personnel.

Learn more…

Learn more…

7

Maintenance

Our service engineers are ready to visit any location worldwide.

We deliver spare parts and components after in post-warranty periods.

We deliver spare parts and components after in post-warranty periods.

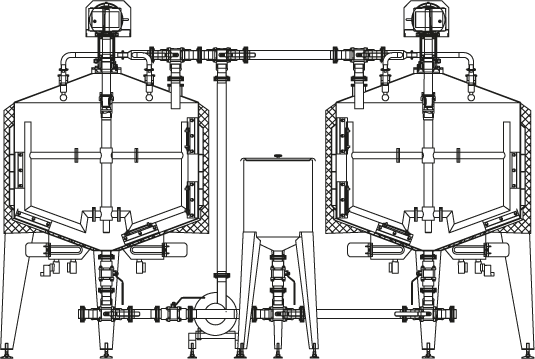

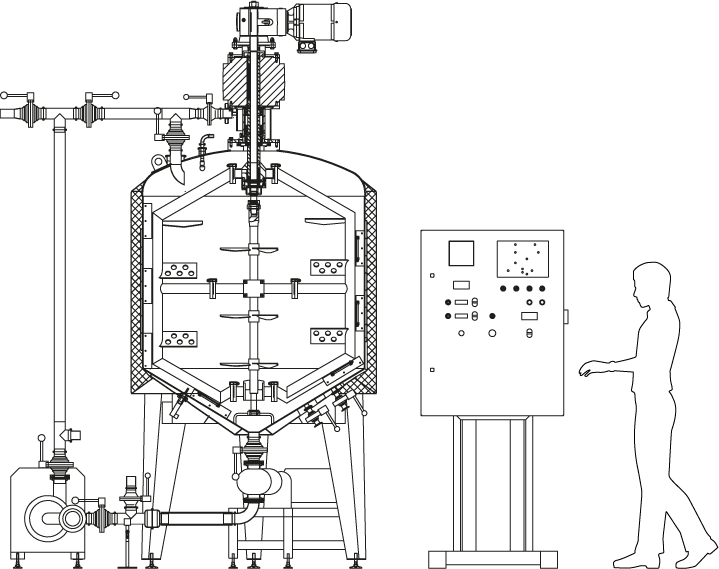

Reactors, Homogenizers

Artlife Techno product range includes cosmetics reactors from 10 to 5,000 l capacity. They are intended for making multicomponent, high-viscosity suspension/emulsion-based products.

Reactors, Homogenizers

Artlife Techno product range includes cosmetics reactors from 10 to 5,000 l capacity. They are intended for making multicomponent, high-viscosity suspension/emulsion-based products.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Product recirculation pump

Recirculates and unloads the product.

Recirculates and unloads the product.

Horseshoe agitator with blades

The agitator has blades to remove the product from the reactor walls during mixing.

The agitator has blades to remove the product from the reactor walls during mixing.

Bottom homogenizer

A homogenizer is located at the bottom of the plant and has a recirculation system.

Its function is product discharging.

A homogenizer is located at the bottom of the plant and has a recirculation system.

Its function is product discharging.

Immersible homogenizer

Located at the middle of the vessel, mills and homogenizes the product without circulating it.

Located at the middle of the vessel, mills and homogenizes the product without circulating it.

Coaxial agitator

A combination of counter-rotating slow and fast agitators. Used for complex composition products. It offers high mixing rate and quality.

A combination of counter-rotating slow and fast agitators. Used for complex composition products. It offers high mixing rate and quality.

Strain gauge system

A strain gauge system is used for component weighing and dosing.

A strain gauge system is used for component weighing and dosing.

Openable lid

To isolate the media, single or double end seals are used.

To isolate the media, single or double end seals are used.

Blades

PTFE blades at the agitator perimeter remove the product from the reactor walls during mixing.

PTFE blades at the agitator perimeter remove the product from the reactor walls during mixing.

Agitator drive

To isolate the media, single or double end seals are used.

To isolate the media, single or double end seals are used.

Control panel

A Siemens controller with a touchscreen for convenient visualization and process control.

A Siemens controller with a touchscreen for convenient visualization and process control.

Dry component feed funnel

Dry components can be fed directly to the homogenizing unit.

Dry components can be fed directly to the homogenizing unit.

Bottom homogenizer

A homogenizer located at the bottom of the plant. Its functions are: recirculation, dry components feed, and product discharge.

A homogenizer located at the bottom of the plant. Its functions are: recirculation, dry components feed, and product discharge.

Product recirculation pump

Recirculates and unloads the product.

Recirculates and unloads the product.

Horseshoe agitator with blades

The agitator has blades to remove the product from the reactor walls during mixing.

The agitator has blades to remove the product from the reactor walls during mixing.

Bottom homogenizer

A homogenizer is located at the bottom of the plant and has a recirculation system.

Its function is product discharging.

A homogenizer is located at the bottom of the plant and has a recirculation system.

Its function is product discharging.

Immersible homogenizer

Located at the middle of the vessel, mills and homogenizes the product without circulating it.

Located at the middle of the vessel, mills and homogenizes the product without circulating it.

Coaxial agitator

A combination of counter-rotating slow and fast agitators. Used for complex composition products. It offers high mixing rate and quality.

A combination of counter-rotating slow and fast agitators. Used for complex composition products. It offers high mixing rate and quality.

Strain gauge system

A strain gauge system is used for component weighing and dosing.

A strain gauge system is used for component weighing and dosing.

Openable lid

To isolate the media, single or double end seals are used.

To isolate the media, single or double end seals are used.

Blades

PTFE blades at the agitator perimeter remove the product from the reactor walls during mixing.

PTFE blades at the agitator perimeter remove the product from the reactor walls during mixing.

Agitator drive

To isolate the media, single or double end seals are used.

To isolate the media, single or double end seals are used.

Control panel

A Siemens controller with a touchscreen for convenient visualization and process control.

A Siemens controller with a touchscreen for convenient visualization and process control.

Dry component feed funnel

Dry components can be fed directly to the homogenizing unit.

Dry components can be fed directly to the homogenizing unit.

Bottom homogenizer

A homogenizer located at the bottom of the plant. Its functions are: recirculation, dry components feed, and product discharge.

A homogenizer located at the bottom of the plant. Its functions are: recirculation, dry components feed, and product discharge.

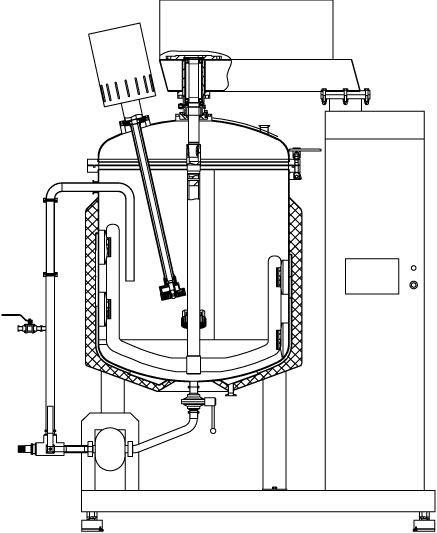

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Product recirculation pump

Recirculates and unloads the product.

Recirculates and unloads the product.

Heating coil unit

Maintains the specified temperature in the reactor heating circuit.

Maintains the specified temperature in the reactor heating circuit.

Coaxial agitator

A combination of counter-rotating slow and fast agitators. Used for complex composition products. It offers high mixing rate and quality.

A combination of counter-rotating slow and fast agitators. Used for complex composition products. It offers high mixing rate and quality.

Piping

Either manual, or automated valves are used. Heating and heat insulation options are available.

Either manual, or automated valves are used. Heating and heat insulation options are available.

Agitator drive

To isolate the media, single or double end seals are used.

To isolate the media, single or double end seals are used.

Control panel

A Siemens controller with a touchscreen for convenient visualization and process control

A Siemens controller with a touchscreen for convenient visualization and process control

Components feeder

Liquid components can be added in-process.

Liquid components can be added in-process.

External homogenizer

An external homogenizer for product recirculation and discharge.

An external homogenizer for product recirculation and discharge.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Cosmetic reactors/homogenizers questionary

Send your contact details for questionary