© 2019 Artlife Techno

Pharmaceutical Equipment

Reactors for injection/infusion solutions, pressure vessels and dry powder mixers.

Pharmaceutical Equipment

Reactors for injection/infusion solutions, pressure vessels and dry powder mixers.

Workflow

1

Requirements Specification

We study the requirements specification, and assist with its development based on the questionnaires filled by the customer.

2

Design

Having the requirements specification, our engineers select the most suitable configuration of standard modules, or design a customized project. Then the managers issue a detailed proposal indicating the equipment configuration and specifications.

Learn more…

Learn more…

3

Manufacturing

After negotiating the price and entering into a contract, we get the final drawings approved by the customer, and proceed with manufacturing.

Learn more…

Learn more…

4

Factory Acceptance Tests (FAT)

After FAT, the products are packaged into crates compliant to the international standards, and shipped to your site.

Learn more…

Learn more…

5

Installation and Commissioning

Our service team visits the customer site for equipment installation and commissioning. We perform equipment piping hook up, and adjustment.

Learn more…

Learn more…

6

SAT Tests and Documentation

During SAT, our team together with you checks the equipment for compliance with the approved specifications, hands over the final documentation packages, and trains the personnel.

Learn more…

Learn more…

7

Maintenance

Our service engineers are ready to visit any location worldwide.

We deliver spare parts and components after in post-warranty periods.

We deliver spare parts and components after in post-warranty periods.

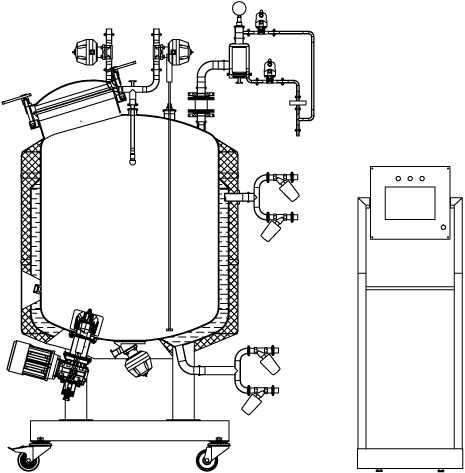

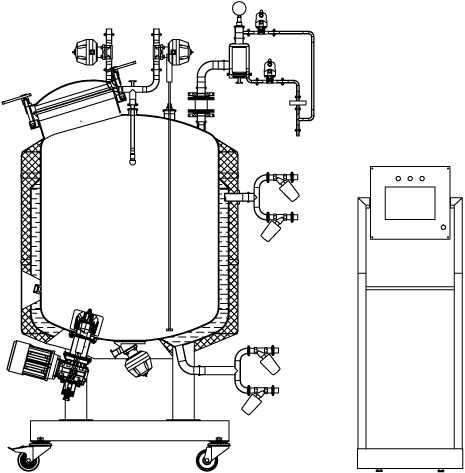

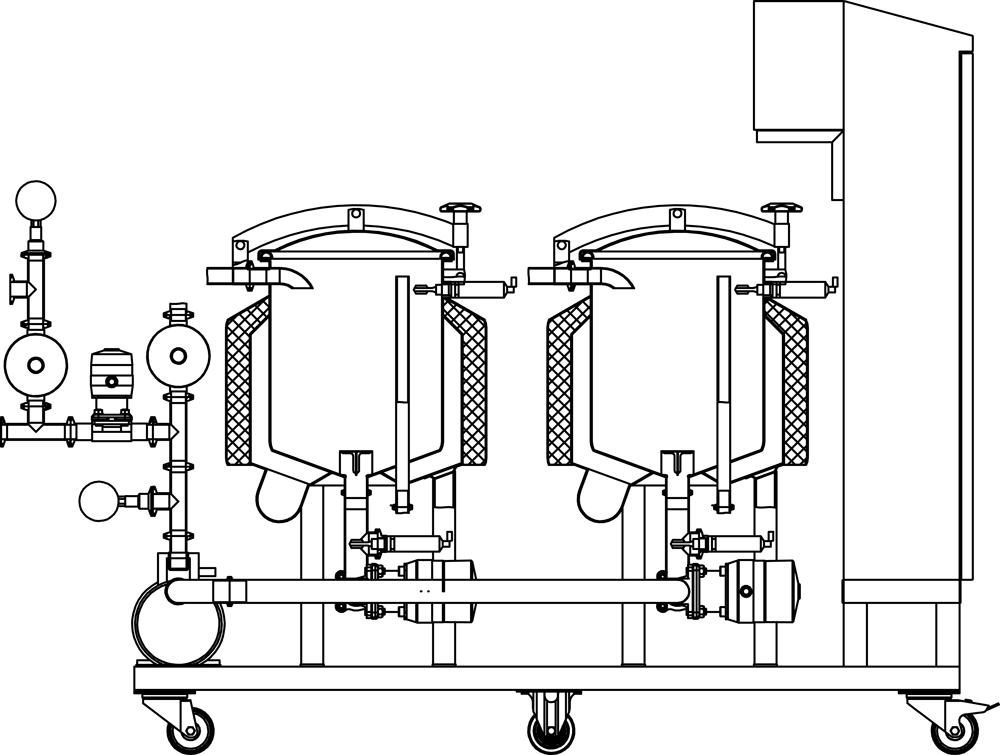

Pharmaceutical Liquid Reactors

Artlife Techno line of products includes reactors for injection/infusion and other pharmaceutical liquids and medications. The capacity range is 10 to 15,000 l. These reactors are mostly used in sterile products manufacturing.

Pharmaceutical Liquid Reactors

Artlife Techno line of products includes reactors for injection/infusion and other pharmaceutical liquids and medications. The capacity range is 10 to 15,000 l. These reactors are mostly used in sterile products manufacturing.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Magnetic stirrer

The stirrer guarantees sterility and efficient mixing since the two vessels are physically separated.

The stirrer guarantees sterility and efficient mixing since the two vessels are physically separated.

Level gauge

A WFI level measurement system.

A WFI level measurement system.

Discharge system

A sterilizable membrane bottom valve with no dead zones.

A sterilizable membrane bottom valve with no dead zones.

Analytical sensor ports

Analytical/instrumentation sensors: pH/rH, DO, temperature, conductivity, etc.

Analytical/instrumentation sensors: pH/rH, DO, temperature, conductivity, etc.

Access manhole

A manhole to access the reactor vessel.

A manhole to access the reactor vessel.

Strain gauge system

A strain gauge system is used for component weighing and dosing.

A strain gauge system is used for component weighing and dosing.

Sampling system

A sterilizable-in-place sampler to monitor the product composition in process.

A sterilizable-in-place sampler to monitor the product composition in process.

Flow meter

A high precision Coriolis flowmeter for accurate component dosing.

A high precision Coriolis flowmeter for accurate component dosing.

Control module

Convenient visualization and process control. A range of automation options: from manual control to fully automated recipe-controlled systems.

Convenient visualization and process control. A range of automation options: from manual control to fully automated recipe-controlled systems.

Control cabinet

Process variable monitoring and control.

Process variable monitoring and control.

Hydrophobic vent filter

Gas input/output as required.

Gas input/output as required.

Spray ball

Completely washes the reactor vessel interior.

Completely washes the reactor vessel interior.

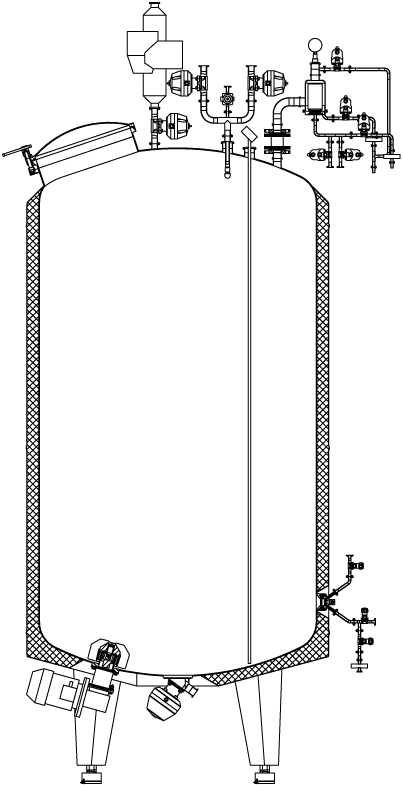

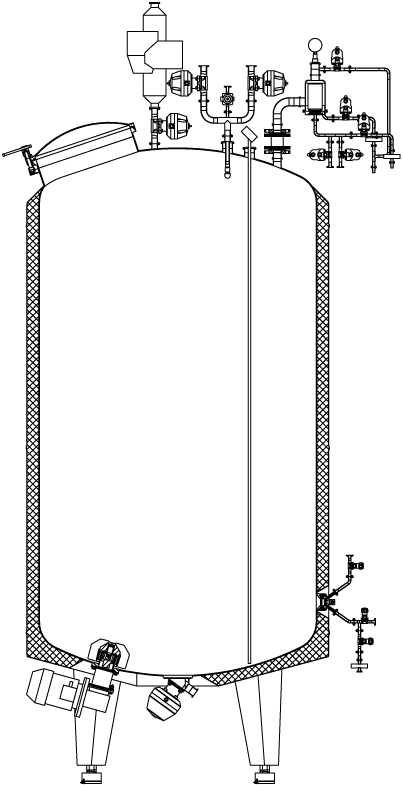

Magnetic stirrer

The stirrer guarantees sterility and efficient mixing since the two vessels are physically separated.

The stirrer guarantees sterility and efficient mixing since the two vessels are physically separated.

Level gauge

A WFI level measurement system.

A WFI level measurement system.

Discharge system

A sterilizable membrane bottom valve with no dead zones.

A sterilizable membrane bottom valve with no dead zones.

Analytical sensor ports

Analytical/instrumentation sensors: pH/rH, DO, temperature, conductivity, etc.

Analytical/instrumentation sensors: pH/rH, DO, temperature, conductivity, etc.

Access manhole

A manhole to access the reactor vessel.

A manhole to access the reactor vessel.

Strain gauge system

A strain gauge system is used for component weighing and dosing.

A strain gauge system is used for component weighing and dosing.

Sampling system

A sterilizable-in-place sampler to monitor the product composition in process.

A sterilizable-in-place sampler to monitor the product composition in process.

Flow meter

A high precision Coriolis flowmeter for accurate component dosing.

A high precision Coriolis flowmeter for accurate component dosing.

Control module

Convenient visualization and process control. A range of automation options: from manual control to fully automated recipe-controlled systems.

Convenient visualization and process control. A range of automation options: from manual control to fully automated recipe-controlled systems.

Control cabinet

Process variable monitoring and control.

Process variable monitoring and control.

Hydrophobic vent filter

Gas input/output as required.

Gas input/output as required.

Spray ball

Completely washes the reactor vessel interior.

Completely washes the reactor vessel interior.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

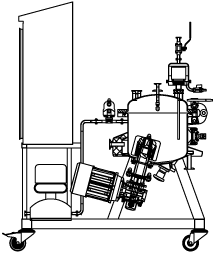

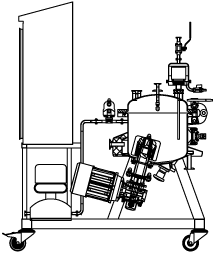

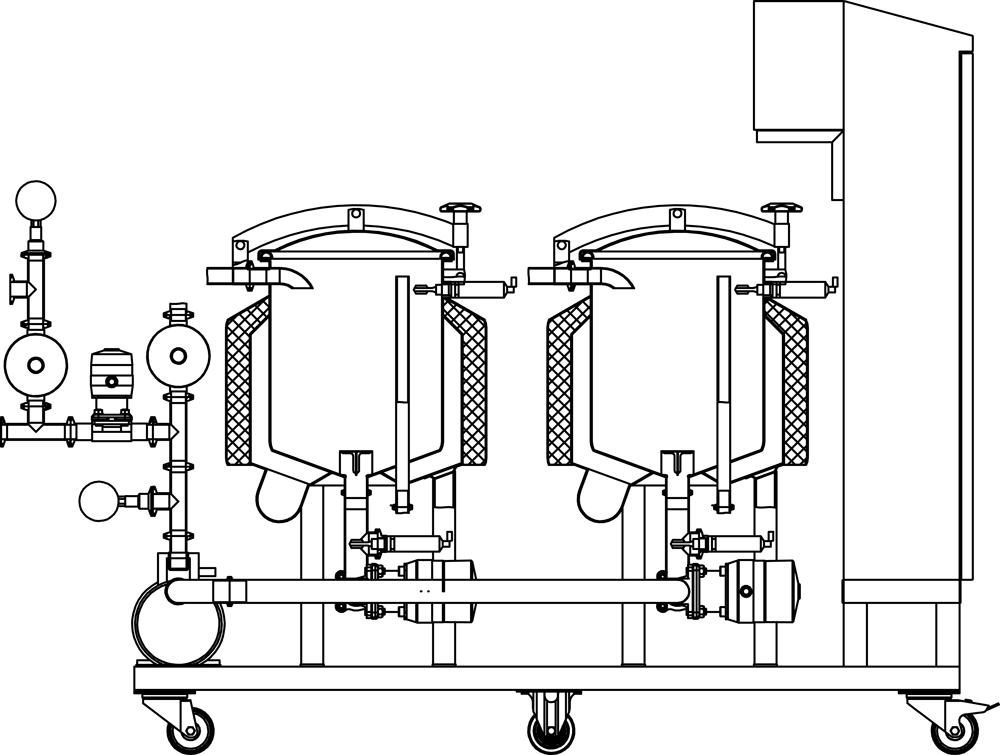

CIP systems

For CIP (Clean-in-Place) washing and sterilization, Artlife Techno makes a number of CIP systems with a range of automation options: from manual control to fully automated systems.

CIP systems

For CIP (Clean-in-Place) washing and sterilization, Artlife Techno makes a number of CIP systems with a range of automation options: from manual control to fully automated systems.

Washing quality control module

Analytical sensors to monitor pH, conductivity of washing/draining liquids.

Analytical sensors to monitor pH, conductivity of washing/draining liquids.

Control panel

A Siemens controller with a touchscreen for convenient visualization and process control.

A Siemens controller with a touchscreen for convenient visualization and process control.

Temperature maintenance system

The system uniformly heats the washing liquid.

The system uniformly heats the washing liquid.

Logger

The logger logs the key wash/sterilization variables.

The logger logs the key wash/sterilization variables.

Sterilization module

The module controls steam supply into the equipment being sterilized, and drains the condensate.

The module controls steam supply into the equipment being sterilized, and drains the condensate.

Washing liquid mixing vessels

The system has as many washing liquid mixing vessels as required.

The system has as many washing liquid mixing vessels as required.

Pumps

The pumps deliver and circulate the washing liquid.

The pumps deliver and circulate the washing liquid.

Piping

Either manual, or automated valves are used.

Either manual, or automated valves are used.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Customized specifications and configurations. The images demonstrate some of the available configurations.

Washing quality control module

Analytical sensors to monitor pH, conductivity of washing/draining liquids.

Analytical sensors to monitor pH, conductivity of washing/draining liquids.

Control panel

A Siemens controller with a touchscreen for convenient visualization and process control.

A Siemens controller with a touchscreen for convenient visualization and process control.

Temperature maintenance system

The system uniformly heats the washing liquid.

The system uniformly heats the washing liquid.

Logger

The logger logs the key wash/sterilization variables.

The logger logs the key wash/sterilization variables.

Sterilization module

The module controls steam supply into the equipment being sterilized, and drains the condensate.

The module controls steam supply into the equipment being sterilized, and drains the condensate.

Washing liquid mixing vessels

The system has as many washing liquid mixing vessels as required.

The system has as many washing liquid mixing vessels as required.

Pumps

The pumps deliver and circulate the washing liquid.

The pumps deliver and circulate the washing liquid.

Piping

Either manual, or automated valves are used.

Either manual, or automated valves are used.

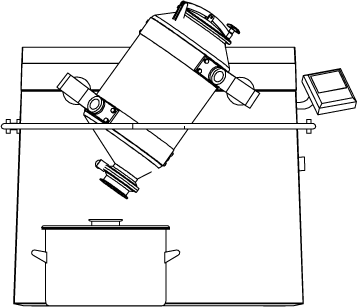

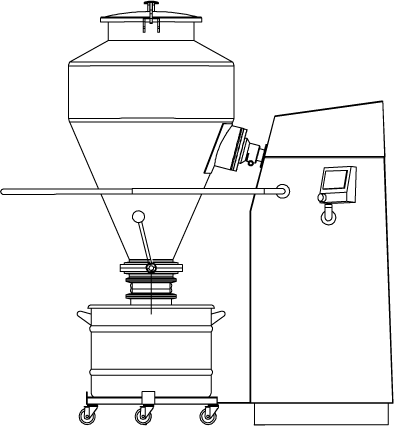

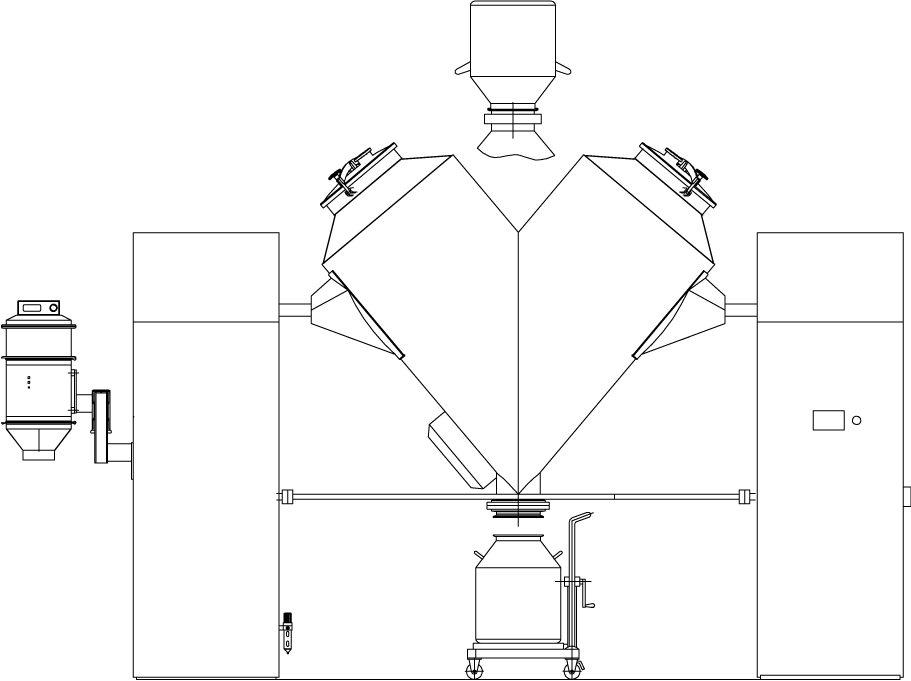

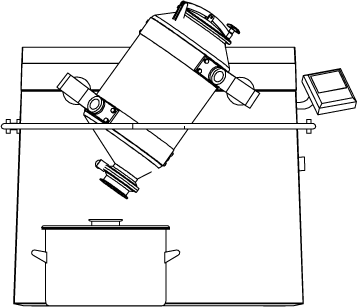

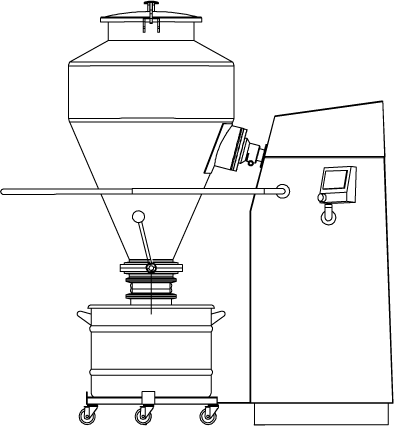

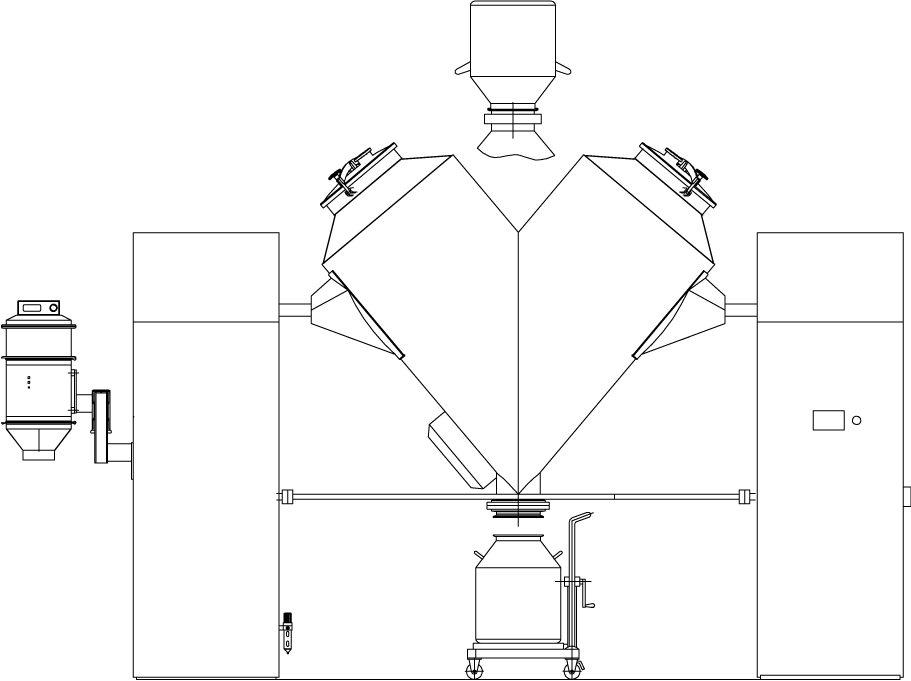

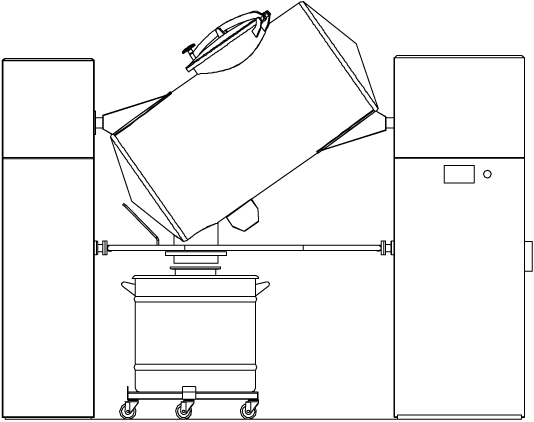

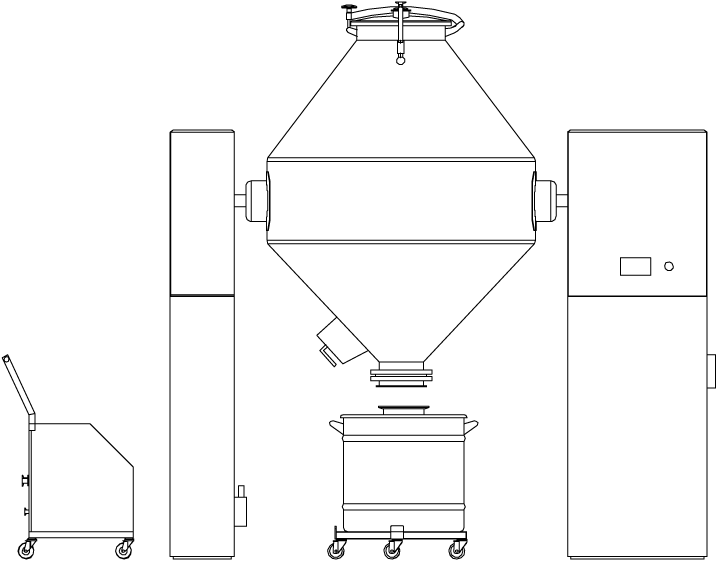

Dry Powder Mixers

Artlife Techno manufactures a range of dry powder mixers. The mixer capacity varies from 10 to 3,000 l. The mixers are intended for making multi-component mixtures for subsequent compression, mixing granules, and any other powder materials not prone to caking.

Dry Powder Mixers

Artlife Techno manufactures a range of dry powder mixers. The mixer capacity varies from 10 to 3,000 l. The mixers are intended for making multi-component mixtures for subsequent compression, mixing granules, and any other powder materials not prone to caking.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Dust-free unloader

Dust-free unloading of dry products.

Dust-free unloading of dry products.

Safety guards

The guards protect the operator. The mixing vessel rotation stops as the guard is lifted.

The guards protect the operator. The mixing vessel rotation stops as the guard is lifted.

Low flowability products mover

Easily unloads low flowability materials.

Easily unloads low flowability materials.

General-purpose vacuum loader (GPVL)

GPVL loads/unloads/moves dry powder products.

GPVL loads/unloads/moves dry powder products.

Container for loading/unloadind

To load/unload product with gravity

To load/unload product with gravity

Control panel

A Siemens controller with a touchscreen for convenient visualization and mixing process control.

A Siemens controller with a touchscreen for convenient visualization and mixing process control.

Mixing vessel

Discharge container

The container is designed to unload, store, and move dry products.

The container is designed to unload, store, and move dry products.

Control panel

A Siemens controller with a touchscreen for convenient visualization and mixing process control.

A Siemens controller with a touchscreen for convenient visualization and mixing process control.

Mixer vessel access manholes

Vessel washing (CIP option available) Manual loading (vacuum loading option available).

Vessel washing (CIP option available) Manual loading (vacuum loading option available).

Lift trolley

To move a container and dock it to the bottom manhole.

To move a container and dock it to the bottom manhole.

Turbomix Mixer

Tilted Mixer

V blender

Product Range:

ТМ-30

ТМ-100

ТМ-200

ТМ-30

ТМ-100

ТМ-200

Product range:

SМ-100

SМ-300

SМ-100

SМ-300

Product range:

V-100

V-250

V-500

V-1000

V-3000

V-100

V-250

V-500

V-1000

V-3000

Dust-free unloader

Dust-free unloading of dry products.

Dust-free unloading of dry products.

Safety guards

The guards protect the operator. The mixing vessel rotation stops as the guard is lifted.

The guards protect the operator. The mixing vessel rotation stops as the guard is lifted.

Low flowability products mover

Easily unloads low flowability materials.

Easily unloads low flowability materials.

General-purpose vacuum loader (GPVL)

GPVL loads/unloads/moves dry powder products.

GPVL loads/unloads/moves dry powder products.

Container for loading/unloading

To load/unload product with gravity

To load/unload product with gravity

Control panel

A Siemens controller with a touchscreen for convenient visualization and mixing process control.

A Siemens controller with a touchscreen for convenient visualization and mixing process control.

Mixing vessel

Discharge container

The container is designed to unload, store, and move dry products.

The container is designed to unload, store, and move dry products.

Turbomix Mixer

Tilted Mixer

V blender

Product Range:

ТМ-30

ТМ-100

ТМ-200

ТМ-30

ТМ-100

ТМ-200

Product range:

СМ-100

СМ-300

СМ-100

СМ-300

Product range:

V-100

V-250

V-500

V-1000

V-3000

V-100

V-250

V-500

V-1000

V-3000

Control panel

A Siemens controller with a touchscreen for convenient visualization and mixing process control.

A Siemens controller with a touchscreen for convenient visualization and mixing process control.

Discharge valve pneumatic actuator

Opens the discharge valve by a control panel command.

Opens the discharge valve by a control panel command.

Mixer vessel access manholes

Vessel washing (CIP option available) Manual loading (vacuum loading option available).

Vessel washing (CIP option available) Manual loading (vacuum loading option available).

Lift trolley

To move a container and dock it to the bottom manhole.

To move a container and dock it to the bottom manhole.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Safety guards

The guards protect the operator. The mixing vessel rotation stops as the guard is lifted.

The guards protect the operator. The mixing vessel rotation stops as the guard is lifted.

Low flowability products mover

Easily unloads low flowability materials.

Easily unloads low flowability materials.

Control panel

A Siemens controller with a touchscreen for convenient visualization and mixing process control.

A Siemens controller with a touchscreen for convenient visualization and mixing process control.

Washing head (CIP)

Completely washes the mixer vessel interior.

Completely washes the mixer vessel interior.

Access manhole

Used for manual product loading, and the mixer vessel maintenance.

Used for manual product loading, and the mixer vessel maintenance.

Discharge valve

Available options:

- manual

- pneumatic remotely controlled actuator

Available options:

- manual

- pneumatic remotely controlled actuator

Movable container

A container for dry product unloading/moving/storage.

A container for dry product unloading/moving/storage.

Drum mixer

Biconical mixer

Product range:

SМ-350

SМ-700

SМ-1000

SМ-350

SМ-700

SМ-1000

Product range:

SMB-500

SMB-1000

SMB-1600

SMB-2000

SMB-500

SMB-1000

SMB-1600

SMB-2000

Vacuum loader module (VLM)

Vacuum components loading into the mixer vessel.

Vacuum components loading into the mixer vessel.

Dust-free unloader

Dust-free unloading of powder materials.

Dust-free unloading of powder materials.

Customized specifications and configurations.

The images demonstrate some of the available configurations.

The images demonstrate some of the available configurations.

Pharmaceutical equipment questionary

Send your contact details for questionary